Hot Products

Xrido Group EFB Processing Equipment

Xrido Group EFB Processing Equipment: Solving the Pain Points of the Palm Oil Industry and Empowering the Upgrade of Alternative Fuels

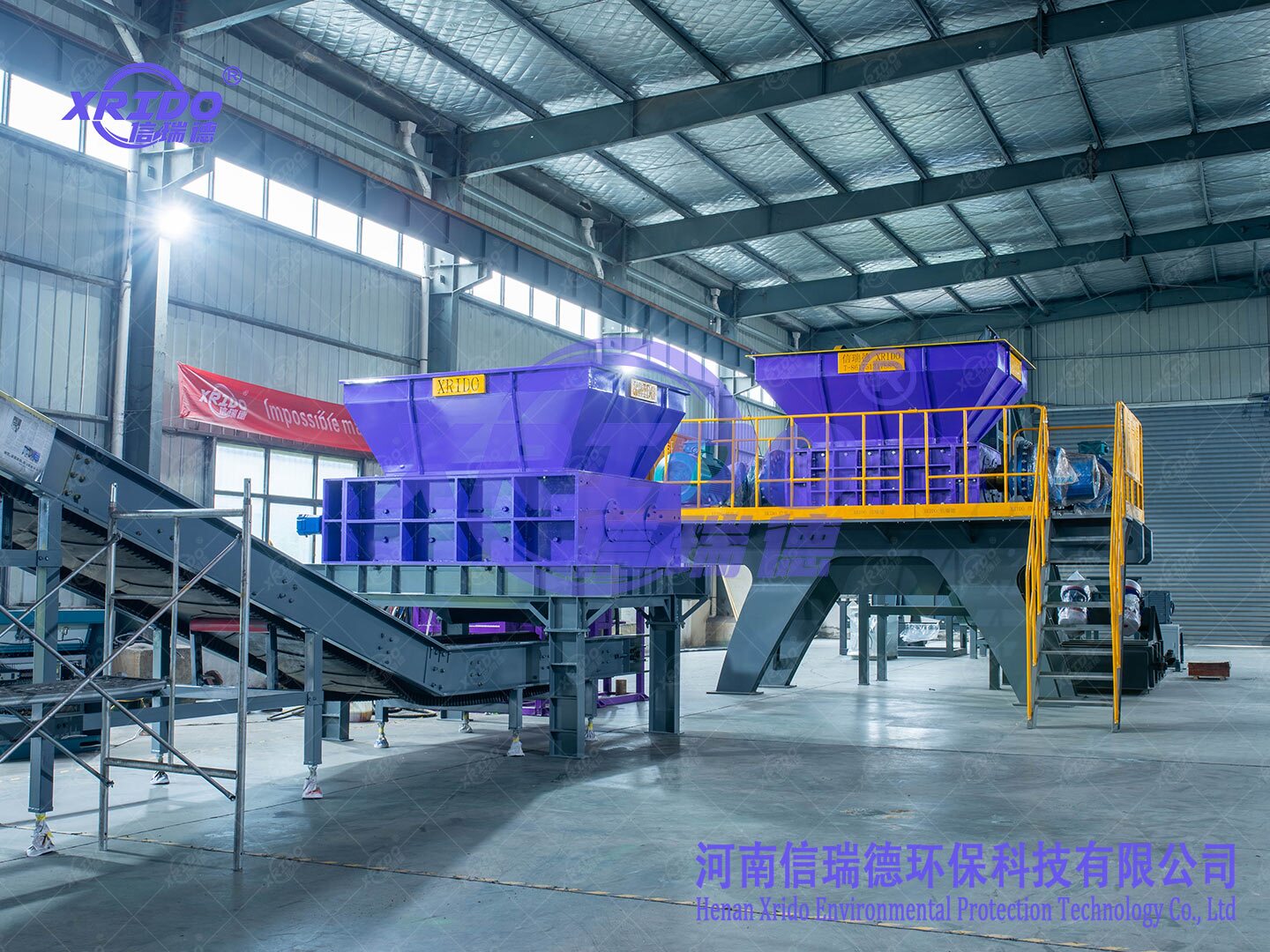

The palm oil industry has long been plagued by the problem of processing empty fruit bunches (EFB) – accumulating and occupying land, rotting and polluting the environment. Traditional processing methods not only fail to create value but also incur high disposal costs. Xrido Group’s EFB processing equipment, through technological innovation, efficiently converts EFB into alternative fuels, solving the industry’s pain points and providing a high-quality resource for energy structure transformation, becoming a “bridge equipment” between the palm oil industry and the environmental energy sector.

The technological highlight of Xrido Group’s EFB processing equipment lies in its targeted solution to the core difficulties of EFB processing. First, addressing the issue of tough and easily entangled EFB fibers, the equipment employs an “interlaced dual-axis cutter” design. The optimized cutter teeth allow for rapid fiber cutting and prevent entanglement, increasing crushing efficiency by 45% compared to traditional equipment. Second, addressing the low fuel quality caused by the high moisture content of EFB, the equipment innovatively uses a “three-stage dehydration and drying process.” First, free water is removed through extrusion; then, waste heat from the palm oil plant is used for preliminary drying; and finally, low-temperature hot air deep drying ensures that the finished fuel’s moisture content remains consistently below 15%, meeting calorific value standards. Finally, considering the transportation and storage needs of alternative fuels, the equipment is equipped with an automatic packaging system that compresses EFB fuel into sealed packages, reducing transportation losses and the risk of moisture absorption.

In the field of alternative fuel applications, the output of Xrido Group’s EFB processing equipment demonstrates broad applicability. EFB alternative fuel can not only be supplied to palm oil plants for their own use but can also be exported to industries such as ceramics, chemicals, and biomass power generation—its combustion process produces no sulfur emissions, and its ash content is less than 5%, fully complying with industrial clean fuel standards. After introducing this equipment, a palm oil plantation in Southeast Asia converts 100,000 tons of EFB (extra flammable fiber) annually into alternative fuels. This not only solves the EFB accumulation problem but also generates over 2 million yuan in export revenue for the plantation, achieving a “win-win” situation for both environmental protection and economic benefits.

Meanwhile, Xrido Group’s EFB processing equipment also prioritizes intelligence and low operating costs. Equipped with an intelligent control system, the entire process can be started with a single button, reducing the need for 3-5 workers. Core components are made of wear-resistant and corrosion-resistant materials, extending the maintenance cycle to over 6 months and reducing annual maintenance costs by 30%. The equipment’s energy consumption design is tailored to the energy supply characteristics of palm oil plants, utilizing waste heat and biogas to further reduce operating costs.

With the increasing global demand for alternative fuels and the rising environmental requirements of the palm oil industry, the value of Xrido Group’s EFB processing equipment is becoming increasingly apparent. It is not only a “game-changer” in solving the EFB processing challenge but also an “enabler” in promoting the palm oil industry’s transformation towards a circular economy and facilitating the green upgrading of the energy structure. Choosing Xrido Group can help palm oil companies reduce costs and increase efficiency, while also contributing to the environmental energy cause, achieving a win-win situation for all parties.

With the increasing global demand for alternative fuels and the rising environmental requirements of the palm oil industry, the value of Xrido Group’s EFB processing equipment is becoming increasingly apparent. It is not only a “game-changer” in solving the EFB processing challenge but also an “enabler” in promoting the palm oil industry’s transformation towards a circular economy and facilitating the green upgrading of the energy structure. Choosing Xrido Group can help palm oil companies reduce costs and increase efficiency, while also contributing to the environmental energy cause, achieving a win-win situation for all parties.