Car Body Shredder

Patented Products

Output Capacity : 2-260t/h

Applicable Material : Car body, scrap aluminum, scrap steel, scrap iron, paint bucket, color steel tile, iron pressure block, motorcycle frame, bicycle frame, waste household appliances, carriage plate, keel bar, rolling gate, waste angle iron and other waste metals.

Product Description

The car shell shredder is a mechanical device specially used to process the shells of scrapped cars. It can tear large car shells into smaller blocks or strips for subsequent recycling, transportation and reuse.

The car shell shredder provides an efficient and environmentally friendly solution for the recycling of scrap cars through efficient crushing technology and automated control. It is an indispensable equipment in the modern automobile dismantling and resource recycling industry.

Applicable car body crusher material:

Car Body, Car Shrell

Car Bale, Pressed Car.

Complete Car (with engine).

WORKING PRINCIPLE

The working principle of the car shell shredder is mainly based on mechanical actions such as shearing, tearing and extrusion, as follows:

• Feeding: The car shell is fed into the feed port of the shredder through a conveyor belt or lifting equipment.

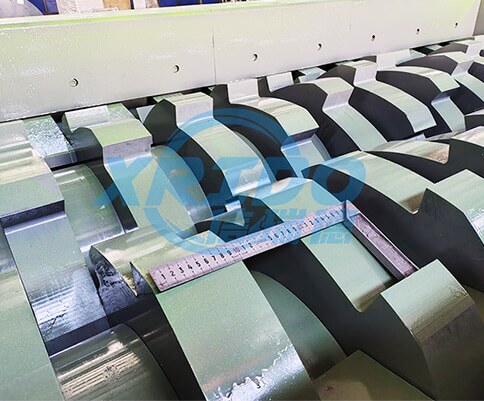

• Crushing: A combination of fixed and moving knives is used. The fixed knife is usually S-shaped and fixed on the top of the knife disc, which plays the role of forced feeding and preliminary crushing. The moving knife is installed on the main shaft. The main shaft is driven to rotate by a motor. The moving knife and the fixed knife cooperate with each other to shear, tear and squeeze the material, and finally tear the car shell into smaller blocks or strips.

• Discharge: The shredded material is discharged through the screen or discharge port, usually in strips or blocks, and the size can be adjusted as needed.

FEATURES

• High efficiency and energy saving: low speed and high torque design, which can complete high-efficiency crushing work at low energy consumption.

• Strong durability: the cutter is usually made of high-strength alloy steel, with high wear resistance and impact resistance.

• High degree of automation: equipped with advanced electrical control system, supporting automatic feeding, automatic reversal and other functions, reducing manual intervention.

• Environmentally friendly design: the equipment is usually equipped with dust removal device to reduce dust pollution.

• Safe and reliable: equipped with overload protection device and emergency stop button to ensure safe operation.

• Wide range of applications: in addition to car shells, it can also be used to crush waste bicycles, motorcycles, home appliance shells, etc.

SHREDDER KNIFE ACCESSORIES

Technical Parameters

| Model | Overall Size(mm) | Crushing Cavity Size(mm) | Power(kw) | Weight(kg) |

| XRD - SZSS - 500 | 2800×1300×1850 | 500×480 | 11×2 | 2200 |

| XRD - SZSS - 800 | 3000×1300×1850 | 800×480 | 15×2 | 2500 |

| XRD - SZSS - 1000 | 3300×1900×2200 | 1000×690 | 22×2 | 5200 |

| XRD - SZSS - 1200 | 3600×2000×2200 | 1200×690 | 30×2 | 6400 |

| XRD - SZSS - 1500 | 4100×2100×2400 | 1500×850 | 55×2 | 9000 |

| XRD - SZSS - 1800 | 5800×2400×3300 | 1800×1206 | 75×2 | 13600 |

| XRD - SZSS - 2000 | 6400×2700×3500 | 2000×1490 | 90×2 | 20100 |

| XRD - SZSS - 2500 | 7500×3200×3800 | 2500×1800 | 110×2 | 22500 |

| XRD - SZSS - 3000 | 8600×3500×4000 | 3000×1800 | 160×2 | 31000 |

(Special - customized types can be customized according to the size and type of materials.)