Rubber Recycling Machine

Input Size : 200-2200mm

Output Capacity : 400-60000kg/h

Product Application : Waste tire treatment system, Waste rubber tire recycling industry

Applicable Material : truck tires, engineering car tires, Bicycle tires, motorcycle tyres, car tires, OTR tyre

Product Description

APPLICABLE

√Waste tire treatment system

√Waste rubber tire recycling industry

√truck tires, engineering car tires

√Bicycle tires, motorcycle tyres, car tires

Tire Recycling Machine:

-

Rubber Shredder

-

Single Hook Puller Machine

-

Steel Wire Separator Machine

-

Tire cutter Machine

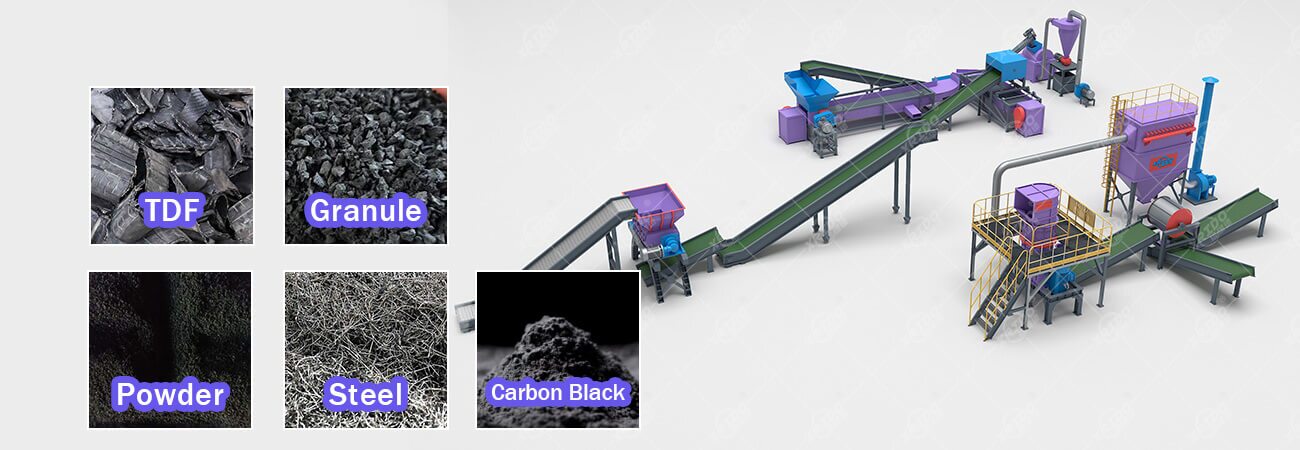

Tire Recycling Process:

Output After Tire Processing

-

Tire Derived Fuel(TDF)

-

Rubber Particles

-

Rubber Powder

-

Steel Wire

WORKING PRINCIPLE

Rubber shredder is driven by the independently double-roller. During the production the material will be pressed accordingly for automatic feed. During the production process of low speed and high torque,there is no spindle entanglement,or jammed equipment,thus improving the production efficiency, the equipment is suitable for various waste rubber products crushing .

FEATURES

1.Ultra-low rotational speed, huge large torque

2.Low noise,less dust

3.Optional motor or hydraulic motor;

4.According to the different nature of materials, customers can freely choose integral shredding blade or assembled detachable blade ;

5.Optional hydraulic forced feeding device, more efficient, fast tear material;

6.Double locking structure at both ends of the shaft head ensures the installation position of the blade and prevents axial displacement;

7.Microcomputer (PLC) automatic control, with the function of start ,stop ,reversal and overload automatic reversal control

Technical Parameters

| Model | Overall Size(mm) | Crushing Cavity Size(mm) | Power(kw) | Weight(kg) |

| XRD - SZSS - 500 | 2800×1300×1850 | 500×480 | 11×2 | 2200 |

| XRD - SZSS - 800 | 3000×1300×1850 | 800×480 | 15×2 | 2500 |

| XRD - SZSS - 1000 | 3300×1900×2200 | 1000×690 | 22×2 | 5200 |

| XRD - SZSS - 1200 | 3600×2000×2200 | 1200×690 | 30×2 | 6400 |

| XRD - SZSS - 1500 | 4100×2100×2400 | 1500×850 | 55×2 | 9000 |

| XRD - SZSS - 1800 | 5800×2400×3300 | 1800×1206 | 75×2 | 13600 |

| XRD - SZSS - 2000 | 6400×2700×3500 | 2000×1490 | 90×2 | 20100 |

| XRD - SZSS - 2500 | 7500×3200×3800 | 2500×1800 | 110×2 | 22500 |

| XRD - SZSS - 3000 | 8600×3500×4000 | 3000×1800 | 160×2 | 31000 |

(Special - customized types can be customized according to the size and type of materials.)