Copper Wire Recycling Machine

Input Size : Customize

Output Capacity : 200-10000kg/h

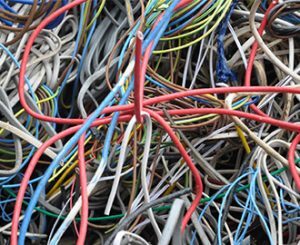

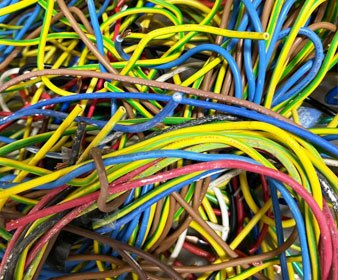

Applicable Material : Car wire looms, Harness wires, Automabile wires, Car bottom wires, Communication cable

Product Description

Cable Granulator Copper Wire Recycling Machine ( also named Cable Wire Granulator ) is a kind of machinery used for recycling waste & scrap copper wire and cables to get copper particles and plastic particles, Cable wire recycling machine is featured with novel design, compact structure, low power consumption and stable performance.

Xrido Cable Granulator Copper Wire Recycling Machine are mainly used to recycle all kinds of waste cable wires, the raw materials will be separated into tiny copper rice and PVC, the applicable range of the wires diameter from 0.3 mm to 20 mm, such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, etc.

Copper Wire Granulator performance

Processing capacity300-500kg/h (It will change when process different material)

Recovery rateOver 98% (It is based on the thickness of cables)

Purity of the finish productsOver 99.8%

Product application as following :Applicable copper wire waste crusher material:

√ Car wire looms

√ Harness wires

√ Automabile wires

√Car bottom wires

√Communication cable

WORKING PRINCIPLE

1st Feed the material into crusher to pulverize the material into 3-4mm granules.

2nd The material will be carried into air separator by belt conveyor and our belt conveyor is equipped with suspended magnet to separate the iron scraps.

3rd By vibration and high press wind the air separator can separate the copper granules from the plastic.

FEATURES

1.Pre-shredder for a wide range of cables

2.Consistent cutting quality

3.High throughput even when processing low-density,bulky cables

4.All-in-one type machine(no screw connections)

5.Low noise, low vibration

6.Control type:PLC

FINAL PRODUCTS

Technical Parameters

| Model | Capacity(kg) | Power(kw) | Dimension(mm) | Weight(kg) |

|---|---|---|---|---|

| XRD - TM - 200 | 50 | 3.9 | 500×800×1700 | 280 |

| XRD - TM - 260 | 80 | 5.75 | 800×1000×1700 | 450 |

| XRD - TM - 400 | 100 - 200 | 18.5 | 1800×1300×1700 | 650 |

| XRD - TM - 600 | 200 - 300 | 42 | 3800×2000×2300 | 4500 |

| XRD - TM - 800 | 500 - 600 | 57 | 4400×2100×2500 | 6500 |

| XRD - TM - 1000 | 800 - 1000 | 75 | 15000×8000×4500 | 7800 |

(The capacity varies depending on the characteristics of the materials. )