Spiral Shredder

Patented Products

Applicable Material : Sponge, Fabric, Leather, Non-woven Fabric,Textile Waste, Clothing waste, Plastic film, Woven bags, MSW, Fishing Net, Soft Material.

Product Description

The spiral soft material shredder is a high-efficiency crushing equipment specifically developed for soft solid waste. It features a low-speed, high-torque design, reliably handling easily tangled materials such as waste clothing, films and woven bags, plastic films, agricultural mulch, household waste, industrial waste, synthetic fibers, and other flexible packaging materials. It achieves uniform and controllable discharge, thus enabling efficient volume reduction and recycling pretreatment.

Anti-Tangling Design: Spiral blades deliver a strong gripping force, effectively processing prone-to-tangle materials like fabrics and ropes.

Applicable Soft Materials:

• Industrial Scrap: sponge, fabric, leather, non-woven fabric,Textile Waste, Clothing waste, etc;

• Chemical Fiber: carpet, workwear,Carpet scraps, etc;

• Plastics: plastic film, woven bags, plastic packaging, BOPP film,Post-consumer plastic, agricultural mulch, PP strapping bands, pet pads, and other rollable packaging materials, etc;

• Solid Waste: Municipal Solid Waste, Big bags, Commeroial & lndustrial Waste, Rigid plastics, Fishing net, Pulper ropes, Agriculture film, etc;

• Biomass: straw, rice straw, branches, Palm Oil EFB, etc.

Features of the Spiral Shredder:

1. A low-speed, high-torque spiral rotor paired with hook-shaped alloy blades provides wear resistance, anti-sticking properties, and concentrated torque, effectively addressing the toughness challenges of soft materials and resulting in stronger tearing force.

2. Materials undergo a four-step closed-loop crushing process: stretching, tearing, shearing, and compression. This thorough disassembly eliminates dead zones, preventing clumping and ensuring a uniform and well-formed finished product free of fragments and large pieces.

3. A permanent magnet synchronous motor allows for speed adjustment based on different materials and free switching between forward and reverse rotation.

4. The discharge particle size is freely adjustable from 10mm to 50mm. By adjusting the chamber length, it precisely matches the needs of different processes such as plastic granulation, textile recycling, and waste paper pulping.

Post-shredding effect demonstration:

How to dispose of pulverized soft materials?

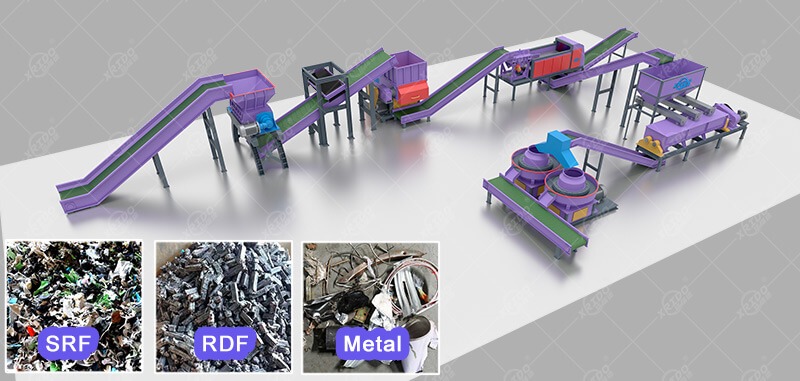

Pulverized soft materials can be efficiently combined with SRF (Solid Recycled Fuel) and RDF (Recycled Dioxide Fuel). The uniform particle size of the pulverized material improves its compatibility with SRF/RDF, optimizing fuel ratios. The mixture can then be used as an alternative fuel in industrial boilers, cement kilns, and other applications, achieving both the reduction and resource recovery of soft materials while reducing fossil fuel consumption. This aligns with environmental protection and energy recycling needs, promoting the efficient utilization of solid waste.

-

Solid Waste Disposal System

-

Biomass pellet briquette Plant

Related Shredders:

Our company offers a wide range of shredders, including those for soft materials, as well as dual-shaft and single-shaft shredders. Dual-shaft models, with their coordinated operation of two shafts, are suitable for processing materials with higher hardness and offer stable crushing efficiency. Single-shaft models excel in small to medium-sized material processing scenarios, offering flexible operation. These three types of equipment can meet the shredding needs of different industries and materials, providing customers with diversified solutions.

Technical Parameters

Special - customized types can be customized according to the size and type of materials.)