Waste Shredder Machine

Patented Products

Type : Double Shaft Shredder, Single Shaft Shredder, Metal Shredder, Solid waste disposal system.

Applicable Material : Industrial waste, Domestic waste, Scrap metal, Medical waste, Solid waste, Plastic, Wood, Bulky waste, E waste etc.

Product Description

A modern waste shredder machine is a highly efficient and intelligent industrial shredding device. Using staggered blades mounted on two parallel rotating shafts (a rotating and fixed blade shaft or dual rotating blade shafts), it applies shearing, squeezing, and tearing action to large, hard, or entangled materials, breaking them into uniform, small pieces (typically 10-100mm in size, adjustable to meet specific requirements). This device is the most common type of industrial shredder, specifically designed for processing waste with complex composition, high toughness, or easily entangled materials (such as metal, plastic, rubber, wood, and electronic waste). Its compact structure, stable operation, and strong adaptability make it widely used in resource recovery, solid waste treatment, industrial production, and other fields, making it a key piece of equipment in the modern circular economy and environmental protection industries.

Everything can be shredded

Applicable Material:

The waste shredder machine can shred nearly all common industrial waste. Typical suitable materials include:

• Metals: scrap steel, aluminum extrusions, copper cables, and stainless steel products (such as appliance casings and industrial scraps);

• Plastics and rubber: waste film (such as PE and PP), plastic pipes, rubber tires, and conveyor belts (including steel cord);

• Composite materials: fiberglass, carbon fiber components, and electronic circuit boards (including plastic-metal composites);

• Other waste: wood scraps, used furniture, fabrics, and cardboard (requiring blade design adjustments). It is particularly adept at processing large, highly resilient, or easily entangled materials (such as rolls of plastic film, bales of scrap metal, and tires), using low shear speeds to prevent rebound and jamming.

Providing one-stop Solution

The company's main products include double-axis shredders, metal crushers, solid waste disposal equipment and renewable resource equipment to meet the needs of different customers. By providing a one-stop solution, XRIDO Group can helps customers solve various solid waste treatment problems.

Solid Waste Management Machine Show:

-

Shredder Machine

-

Crusher Machine

-

RDF Machine

-

Baler Machine

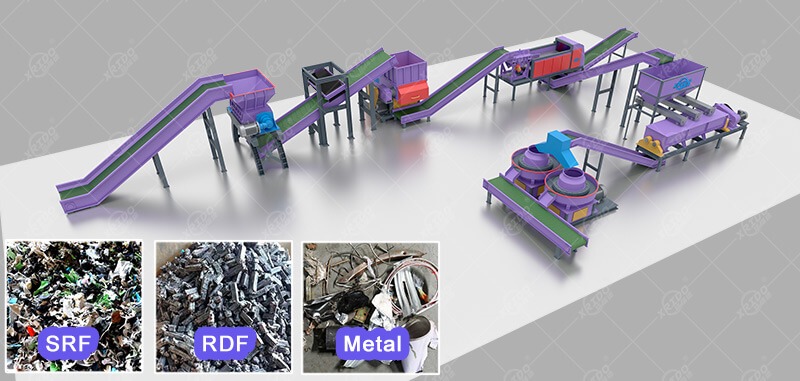

Waste crushing, sorting and recycling system:

The solid waste disposal system can be customized according to the actual materials.-

Solid Waste Disposal System

-

Waste Metal Recycling System

-

Biomass pellet briquette Plant

-

Waste Tire Disposal System

Process:

• Shredding: Solid waste entering the shredder is gradually broken down by the shearing, tearing, and squeezing action of the twin-shaft blades. The machine automatically adjusts the blade speed and torque according to a pre-set program to accommodate materials of varying hardness and toughness. During the shredding process, large solid waste is gradually broken down into smaller pieces.

• Discharge: The shredded, smaller materials are discharged through the discharge port and into the hopper. The hopper can be equipped with a screen to filter the discharged material, returning any that does not meet the size requirements to the shredder for further shredding.

• Sorting: Using magnetic separation, eddy current separation, air separation, gravity separation (gravity separation), and optical separation equipment, different types of materials, such as combustibles, metals, non-ferrous metals, and bottles, are separated for recycling or subsequent processing.

• Baling or RDF Briquetting: Sorted solid waste, including waste paper, plastics, metals, and fiber, is compressed and bundled. Alternatively, the separated SRF is the combustible component (such as plastic, paper, wood, fabric, etc.), which is then processed into block fuel with a certain calorific value, regular shape and high density, which is RDF.

FINAL PRODUCT

Discharge particle size can be customized.

Core Advantages

1. Superior Adaptability: Processes multiple materials and complex structures.

2. Efficient and Stable Crushing: Low Energy Consumption and High Output.

3. Intelligent, Safe, and Reliable: Equipped with PLC and Overload Protection.

4. Environmental Compliance: Complies with EU CE, China GB, and other environmental standards.

5. Flexible Customization: The tooling, chamber, output size, and drive system can be customized to meet user needs.

Details of double shaft shredder

FEATURES

• Intelligent Control: Equipped with a PLC or industrial computer system, it monitors parameters such as motor load, tool wear, and feed speed in real time, automatically adjusting operating modes (e.g., reverse rotation and unloading in the event of a material jam), and supports remote operation and fault diagnosis.

• Safety Protection: Integrated emergency stop button, overload protection, and anti-reverse device prevent equipment damage or safety accidents caused by foreign objects or overload.

• Easy Maintenance: Tools can be quickly removed and replaced (hydraulic adjustment is supported on some models), and a wear monitoring system provides early warning of maintenance needs, reducing downtime.

Technical Parameters

| Model | Overall Size(mm) | Crushing Cavity Size(mm) | Power(kw) | Weight(kg) |

| XRD - SZSS - 500 | 2800×1300×1850 | 500×480 | 11×2 | 2200 |

| XRD - SZSS - 800 | 3000×1300×1850 | 800×480 | 15×2 | 2500 |

| XRD - SZSS - 1000 | 3300×1900×2200 | 1000×690 | 22×2 | 5200 |

| XRD - SZSS - 1200 | 3600×2000×2200 | 1200×690 | 30×2 | 6400 |

| XRD - SZSS - 1500 | 4100×2100×2400 | 1500×850 | 55×2 | 9000 |

| XRD - SZSS - 1800 | 5800×2400×3300 | 1800×1206 | 75×2 | 13600 |

| XRD - SZSS - 2000 | 6400×2700×3500 | 2000×1490 | 90×2 | 20100 |

| XRD - SZSS - 2500 | 7500×3200×3800 | 2500×1800 | 110×2 | 22500 |

| XRD - SZSS - 3000 | 8600×3500×4000 | 3000×1800 | 160×2 | 31000 |